What is a suede machine and what role does it play in textile finishing?

Suede machines are key equipment used in textile finishing. Their basic principle is to gently rub high-speed rollers against the fabric surface, breaking the yarn or fiber surface and causing the fibers to slightly stand upright, creating a uniform, fine nap. This finishing process significantly enhances the fabric's tactile and visual quality without disrupting its overall structure. Suede treatment not only makes the fabric surface softer and more comfortable to wear or use, but also creates a warm, soft suede sheen, enhancing the fabric's appearance and texture. Furthermore, the surface nap provides warmth, helping to trap air and improve thermal insulation. As a high-value-added finishing method, suede treatment is widely used in intimate apparel, bedding, home textiles, automotive interiors, and synthetic leather, effectively enhancing product quality and market competitiveness.

During operation, suede machines can adjust tension, fabric guiding, roller speed, and reciprocating frequency to achieve varying degrees of suede effect, depending on the fabric type and requirements. Common abrasives include sandpaper, emery paper, ceramic fiber rollers, and carbon fiber rollers. Different abrasives significantly affect the napping effect and texture of fabrics.

What types of suede machines are there?

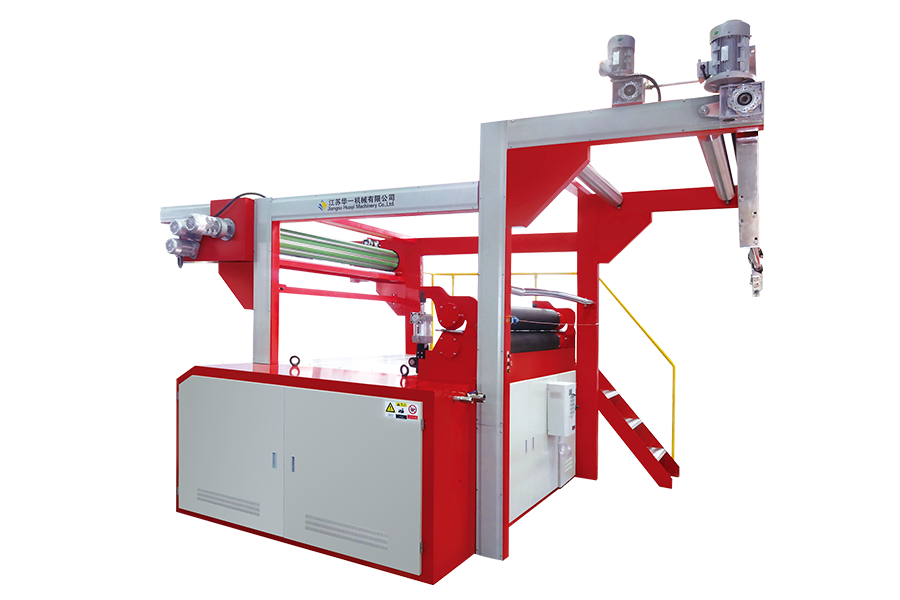

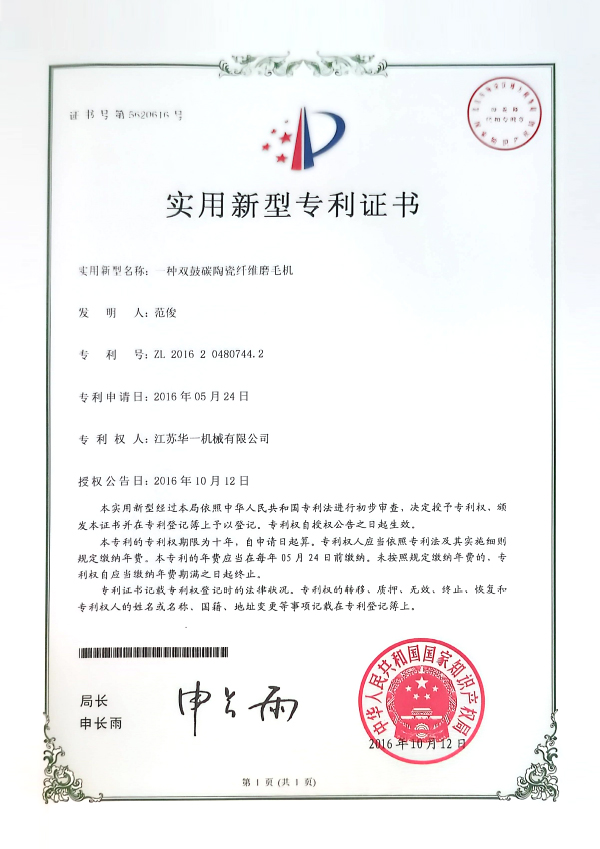

Jiangsu Huayi Machinery Co., Ltd. has developed a variety of high-performance suede machines to meet the diverse fabric and suede needs in the market. Suede machines can be categorized into the following typical models based on their structural design and applicable fabrics:

Planetary Carbon (Ceramic) Fiber Sueding Machine for Woven Y-Model: This model features a planetary design suitable for all types of woven fabrics. It uses high-performance carbon fiber or ceramic fiber as the suede roller material, offering strong wear resistance and excellent thermal stability. The planetary transmission structure allows the roller to rotate around its central axis while simultaneously rotating on its own, ensuring a larger contact area and longer contact time between the fabric and the roller, resulting in a more uniform and deeper suede effect. This equipment is particularly suitable for deep processing of high-end woven fabrics such as corduroy, wool, and twill.

Planetary Carbon (Ceramic) Fiber Sueding Machine for Knitting X-Model: This model is designed specifically for knitted fabrics. It utilizes the same planetary structure as the Woven Y-Model, but features optimized fabric tension control and fabric guiding systems to accommodate the soft and easily deformable nature of knitted fabrics. Through the gentle action of carbon fiber or ceramic fiber rollers, it achieves a gentle and uniform suede finish on knitted fabrics, preventing stretching or deformation while effectively preserving the fabric's original elasticity and flexibility. This machine is widely used for fine finishing of highly elastic and comfortable fabrics such as sportswear, underwear, and babywear.

Vertical Combined Sueding Machine MM-Model: This model offers a compact design and flexible operation, making it ideal for small and medium-sized businesses and workshops with limited production space. Its vertically arranged roller system saves floor space while achieving highly efficient suede processing. The machine supports quick material changes and continuous processing of multiple fabrics, including cotton, polyester, linen, and blends. It is particularly suitable for high-variety, low-volume production environments with frequent order changes. This model offers high adaptability and stability for fabric processing, helping to increase overall production capacity and flexible production capabilities to meet diverse market demands.

Horizontal Combined Sueding Machine MW-Model: This model features a stable structure suitable for all-weather, high-load operation and is particularly well-suited for production scenarios requiring high-volume, long-duration continuous processing. Its horizontal structure ensures smooth fabric loading and unloading, reducing uneven tension and wrinkling, and ensuring consistent sanding quality. Suitable for wide-width fabrics such as home textiles and apparel, this machine offers extremely high production capacity and efficiency, making it a popular choice among large garment factories and home textile companies. Its composite grinding roller system can also be customized to achieve integrated multi-stage sanding and shaping.

High-Speed Dry/Wet Sueding Machine for Polyester SMA382C-Model: This high-speed, dual-purpose dry/wet sanding machine is specifically designed for polyester fibers and their composites. Its intelligent control system allows for switching between dry and wet sanding processes, flexibly adjusting the sanding method to suit the characteristics of different fabrics. In wet sanding mode, the atomizing nozzle sprays a fine mist of water, reducing frictional heat generated between the fabric and the abrasive, effectively preventing fiber melting or deformation, and protecting the fabric's surface integrity and color fastness. This machine is widely suitable for surface treatment of polyester-based functional fabrics such as imitation leather, microfiber fabrics, and imitation suede. It maintains a fine velvety surface while enhancing softness and breathability, making it particularly suitable for high-end applications in sports, outdoor, and footwear.

Diamond Emery (Dry) Wet Sueding Machine for Synthetic Leather LMH815-Model: Designed specifically for synthetic leather, the LMH815 utilizes high-strength diamond abrasive, offering excellent grinding power and durability. It effectively treats artificial leather surfaces, imparting a unique suede texture. This machine supports both dry and wet sanding modes, allowing flexible adjustment of process parameters based on material thickness and properties. Dry grinding mode enables rapid, coarse grinding, improving production efficiency. Wet grinding mode effectively controls friction temperatures to avoid material deformation or scorching, making it particularly suitable for products requiring exceptional surface aesthetics and wear resistance, such as high-end shoe uppers, artificial leather sofas, and automotive seat upholstery.

What operational details should be considered when using a suede sanding machine?

Using a suede sanding machine involves adjusting and precisely controlling multiple parameters. Operators must flexibly adjust these parameters based on the fabric type, desired effect, and process requirements. The following are general operating procedures and precautions:

Equipment Commissioning: Select the appropriate grinding roller material and equipment structure based on the characteristics of the fabric. Parameters such as the grinding roller gap, fabric tension, and fabric feed speed should be carefully adjusted. For planetary suede sanding machines, the appropriate rotation trajectory and angle should also be set to ensure sufficient and uniform contact between the fabric and the abrasive throughout the entire process, achieving the desired suede effect.

Sanding Method Selection: Choose between dry or wet sanding based on the fabric's tolerance and desired effect. Dry sanding is suitable for most conventional fabrics, while wet sanding requires an efficient spray system. By adding an appropriate amount of water mist or lubricant, the system reduces frictional heat on the fabric surface, minimizing the risk of wear and improving the overall protection and stability of the processed fabric. This method is particularly suitable for processing sensitive materials such as microfiber and imitation leather.

Fabric Guiding and Tension Control: The fabric must be flat and wrinkle-free before entering the sanding area to ensure uniform sanding. Precise tension control adjusts the infeed and outfeed tension to ensure stable material tension throughout the entire sanding process, preventing quality issues such as stretching, curling, or breakage. This is particularly critical for knitted or highly elastic fabrics.

Post-Sanding: After sanding, appropriate post-treatment processes, such as heat setting, hot air drying, or cold calendering, are required depending on the fabric type. This ensures the fabric maintains its upright shape and soft feel, prevents deformation or shedding during washing, and improves the overall quality, appearance, and lifespan of the finished product.

Safety and Maintenance: Operators must always observe safe operating procedures and avoid placing hands or tools near the high-speed grinding rollers while the machine is operating. In terms of daily maintenance, the wear of the grinding roller and the degree of abrasive consumption should be checked regularly, aging parts should be replaced in time, and key parts such as the transmission system and tension control mechanism should be lubricated and maintained to ensure long-term stable and efficient operation of the equipment.